Miles Coverdale’s translation of Psalm 105 in the Book of Common Prayer elevated iron from metallurgical to literary significance. The story of Joseph being sold unjustly as a bondservant — “Whose feet they hurt in the stocks: the iron entered into his soul” — shames flaccid times like ours. And iron’s virtues excel not least of all in cooking, where it can enter literally into our bodies and, who knows, maybe our souls too.

Joseph just got things started. Think of the first ironclads, Monitor and Merrimac, hammering away at each other at Hampton Roads in 1862, of the dreadnoughts that put paid to Nelson’s wooden walls, of Agatha Christie’s ironclad alibis, of the verse in Christina Rossetti’s great carol: “Earth stood hard as iron, water like a stone.” Fear- some, elemental stuff iron is; it enjoys place after all in the Periodic Table as “Fe.” It goes back a long way too, to the “Iron Age,” they tell us. Somewhere in that distant past, our ancestors began to prepare their food in it — and the habit stuck. Despite its displacement in many uses by “innovative” materials like its younger cousin steel, iron continues to punch like a heavyweight in the kitchen.

This at first seems odd. At least since the 1950s, home kitchens have been deluged by gadgetry, much of it peddled as labor-saving convenience. Some of this was worthy — food-processors do our slicing and chopping, stand-mixers knead and blend; some of it, like electric can-openers and microwaves, dubious. My early memory of cookware recalls my mother’s stainless-steel, copper-bottomed “Revere Ware,” from what was by American standards an ancient company (1790s) traceable to silver/coppersmith Paul Revere of “the British are coming” fame. With its relentless R&D, streamlined manufacturing and intense marketing to the burgeoning postwar middle-class, Revere Ware was an American classic of a particular historical moment. Like a lot of such classics it has faded away to near nothing in the twenty-first century. It faded away too in my kitchen, as the pans aged out and I learned that the problem they were invented to solve — stainless steel conducts heat unevenly, a difficulty that could be overcome with copper bottoms — was no problem at all with iron.

Here the ancient actually beats out the modern. Three examples stand out in my own kitchen history. In reverse chronological order of my discovery of them, the first and only the first is American.

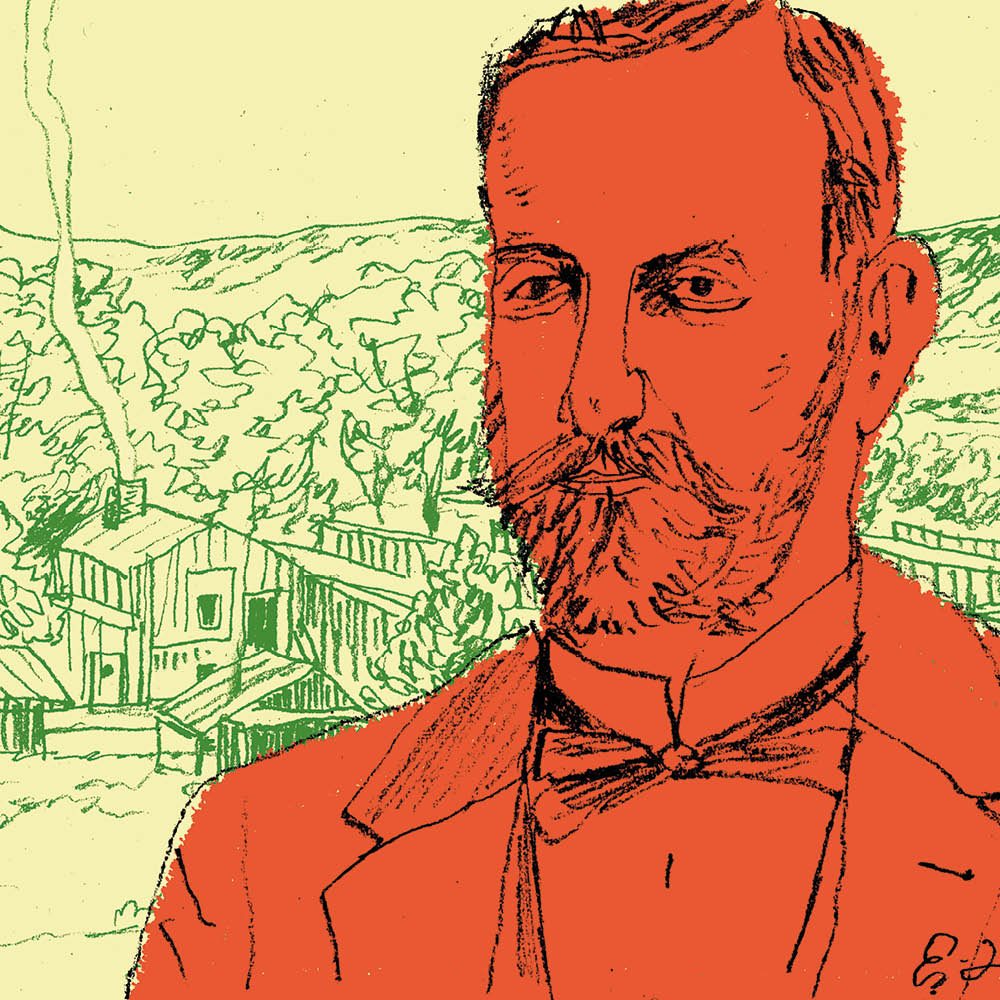

Lodge Cast Iron was not the first but has remained the longest-running cast iron foundry in the American cookware business. Joseph Lodge founded the company in 1896 in South Pittsburg, Tennessee. It has remained there, in the Sequatchie Valley and in the family, ever since. What Lodge made then, they make now and more or less the same way, allowing for automation, a modestly broadened product line and greatly increased capacity. An induction furnace heats pig iron, recycled steel and alloys to 2,800 degrees Fahrenheit. Silicone and binding agents join the molten mix, which is then cast into sand molds, a technique that has been around since the fifth century BC. After cooling, the pans or pots are shaken out, cleaned, their edges smoothed and then, to finish, pre-seasoned at high temperature with vegetable oil. The result is a fine cooking instrument, suitable for just about anything, on the stove top, in the oven — or for that matter over the campfire, though I have no experience in this outdoor department. The pans are heavy (the big ones may take two hands to lift), and they take a bit of time to heat compared, for instance, to the stainless steel Reveres. But heat they do, with all the serene evenness and retentiveness of their primary element. Until recently, they came in but one hue, black.

Lodge products are estimable on two other solid counts that have nothing to do with marketing smoke and mirrors. They perform superbly — and they are still “Made in the USA,” that identifier once attached to just about anything made that was made (and as could be said of “Made in England” before that). My great Lodge skillet was a gift from my daughter-in-law, a fine southern cook who grew up with iron in her mother’s kitchen and cooks grits like no other. Other firms, as James Panero noted with affection in The Spectator World’s March 2022 issue, have produced fine cast iron too, though no longer in the US. My kitchen is the resting place for two of his favored Griswold skillets, cast around mid-century in Erie, Pennsylvania. Alas, Griswold called it quits in 1957 — and I am told its products have growing value as antiques. I will settle for their value as well-made tools that only improve with use and age.

My two other offerings of kitchen iron come from the Old World. “First, Finest, Favorite” is how the French firm Le Creuset none too modestly describes its enameled cast-iron pots and pans. You will find them today in fancy shops with names like “The Happy Cook,” on the top-price shelf and in an array of colors. If a cooking pot can be said to be beautiful, then it’s probably a Le Creuset. The company (like Lodge, still small-town based, in Fresnoy-le-Grand in northern France, independent and privately held) dates to 1925, the brainchild of two Belgians: casting specialist Armand Desaegher and enamel expert Octave Aubecq. Le Creuset (literally, “the cauldron”) pans are cast in the traditional sand molds, but what sets them apart is their coating with layers of enamel, a light sand-shade on the inside and choices from a wide color palette on the out- side. They looked as good as they cooked: appearance and function finely matched. After World War Two, French-American industrial designer Raymond Loewy worked with the company to produce a streamlined series of pots and casseroles for moderne tastes. Le Creuset is a classic example of how to make a good thing, as in cast iron, better. Some say it actually cooks better than its un-enameled predecessors though I cannot tell. It is easier to clean and certainly brightens up the kitchen; you won’t want to keep it in the cupboard. In 2005, Lodge paid Le Creuset the ultimate competitor’s compliment with the introduction of its own line of multicolored enameled cast iron, “offering the performance of European brands at a much more affordable value.” But who knows? Perhaps the mystique of that “Made in France,” cast into every Le Creuset piece, sustains its premium price. Something must keep serious cooks forking over. I count myself among the fortunate who have never had to buy a Le Creuset. Of my small collection, two well-worn flame-red cocottes were inherited from my mother and date to the late Fifties. The third was the gift of my sister-in-law: one of the svelte Loewy-designed coquilles in black (now discontinued). The fourth was a gift from my son’s old prep school master and a fine cook too: a square grill pan in artichoke green.

Though heavy, cast-iron pots and pans are portable. In fact, they are just about guaranteed to follow you through life’s wanderings, salad days to dotage. My third example of kitchen iron emphatically is not portable: it is more like an anchor. An AGA range, weighing in at 1,300 pounds or so of cast iron, is no doubt the heaviest thing you can put into your kitchen. (In fact, before you do, you must check the foundation.) Spectator contributor Hannah Moore has praised AGA as the other secret ingredient for producing the best roast potatoes (the other is goose fat). She also tips us off to another sly truth about AGA: it is the sort of thing that you do not obtain, but have. Sure, you can buy one (price: around $5,000 to $25,000), but more often — and here I am not at all scientific — you buy or move into a house where an AGA is comfortably ensconced already. Mrs. Moore lives in Sussex: I do not know in what sort of house though I imagine something with some age on it. Her AGA will probably have gone some miles too.

My AGA, from boyhood, was manufactured in the 1930s, not long after blind Swedish physicist Gustaf Dalén invented a stove meant to simplify cooking and perform multiple other household tasks. Our AGA had a hot water reservoir with a garden-like tap in front — enough, in the words of an old ad, to provide “three hot baths daily and water for all the washing-up.” What more could you ask? The AGA’s secret was a relatively small energy source that burned constantly, heating a large piece of cast iron engineered into multiple radiant ovens of differing temperature and large circular burners on top that varied from hot center to cooler edges. Ours resided in an alcove in a substantial house in the Netherlands where my family lived sixty years ago. It was a two-class house built between the wars, its still operational electric call-board — Blau Slaapkamer, Rose Slaapkamer, Eetzaal, Groot Hal and so forth — silent witness to vanished staff. AGAs of that era burned solid fuel, coke or anthracite. This one, which dominated the large, tile-floored kitchen, was near the door of the coal cellar, and part of my nightly task was shaking and removing the ash and restoking the fire, which in that damp climate burned around the clock and just about year-round.

AGAs require practice and patience to use well, not just to decorate the kitchen and warm the Wellies. Until recent models, they were notoriously un-adjustable and had their fixed ways. But once you learned their ways, you had a steadfast friend for life. AGAs are still made in Shropshire. The iron casts until a few years ago came from a foundry in Coalbrookdale, cradle of the Industrial Revolution where they made wings for Lancaster bombers during the war. AGAs are as English as Jaguar and MG used to be, though sadly ownership migrated in 2015 to the Middleby Corporation, a global provider of commercial kitchen equipment headquartered near Chicago. You can now buy an all-electric AGA in a rainbow of colors (until the 1950s, all were cream enamel) with, yes, digital touch controls. I cannot say if this is a wise idea but do begin to worry when the old iron beast gets touted with silly phrases like “Progressively Modern with Traditional Values.”

If you are like most mortals, you will only ever experience an AGA vicariously. You will find them popping up from time to time as furniture in crunchy-gravel dramas on Masterpiece Theatre, most recently in an admirable biographical film of the early life and conversion of C.S. Lewis, The Most Reluctant Convert. It is just a walk-on: Lewis goes to the kitchen of his modest house near Oxford, “The Kilns,” to make a cup of tea on the old cream AGA. This is comforting. Lewis died in 1963, the year I first met AGA. He was only sixty-seven — fewer years by far, I will wager, than your average AGA will faithfully heat the kettle, cook the goose, roast the potatoes and much else. Mine — AGAs seem to encourage a sense of possessiveness — survived even the Nazis, who commandeered our house for top brass in 1940 and for whom the resident AGA, then still a youngster, presumably turned out schnitzel and strudel as good as any back in the Fatherland.

Like the estimable Lodge and Le Creuset pans that you actually can afford, AGA is iron and therefore in it for the duration. When nothing much else lasts anymore (it isn’t intended to — “You need an update!”) and when so much once deemed good in our culture is under siege, these three nationalities of iron, American, French and English, proudly dissent. You think of those wartime posters: “VICTORY is in the KITCHEN.” If you’re cooking with iron, you can count on it.

This article was originally published in The Spectator’s July 2024 World edition.

Leave a Reply